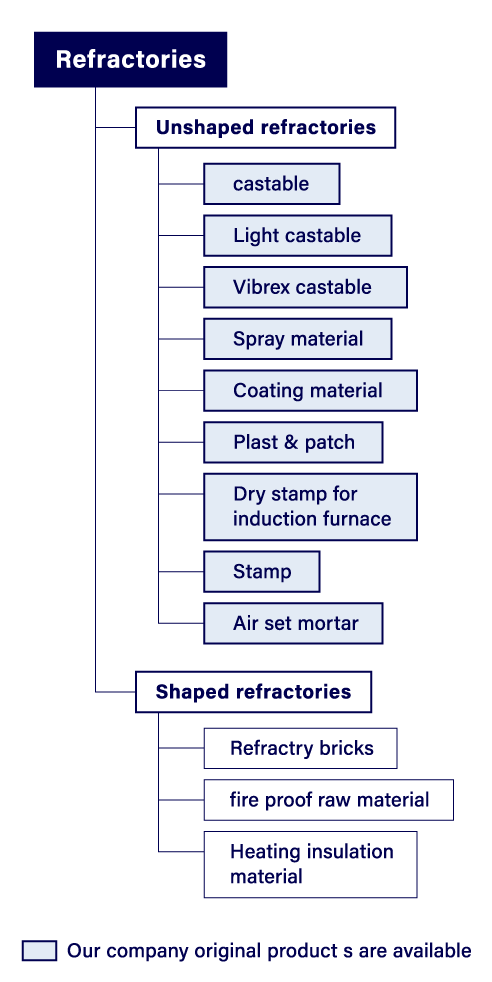

We manufacture and sell a wide variety of products such as various unshaped refractories (high-strength castables, fire-resistant castables, heat-insulating castables, plast materials, patching materials, air set mortars, dry stamps for induction furnace, coating materials, ramming materials, spray materials).

We analyze our unshaped refractories from the view point of not only the specifications but also the "sensitivity" of professional users which is difficult to quantify, and feed them back to the product. By refining the quality over and over again, we are aiming at creating products to ensure certain effects.

We have installed the state of the art production equipment for a production system responding to technology with daily progress and growing.

We conduct thorough quality control to sustainably supply high-quality product.

In order to produce higher quality products, we are particular about the quality of raw materials, procure and mix them in-house.

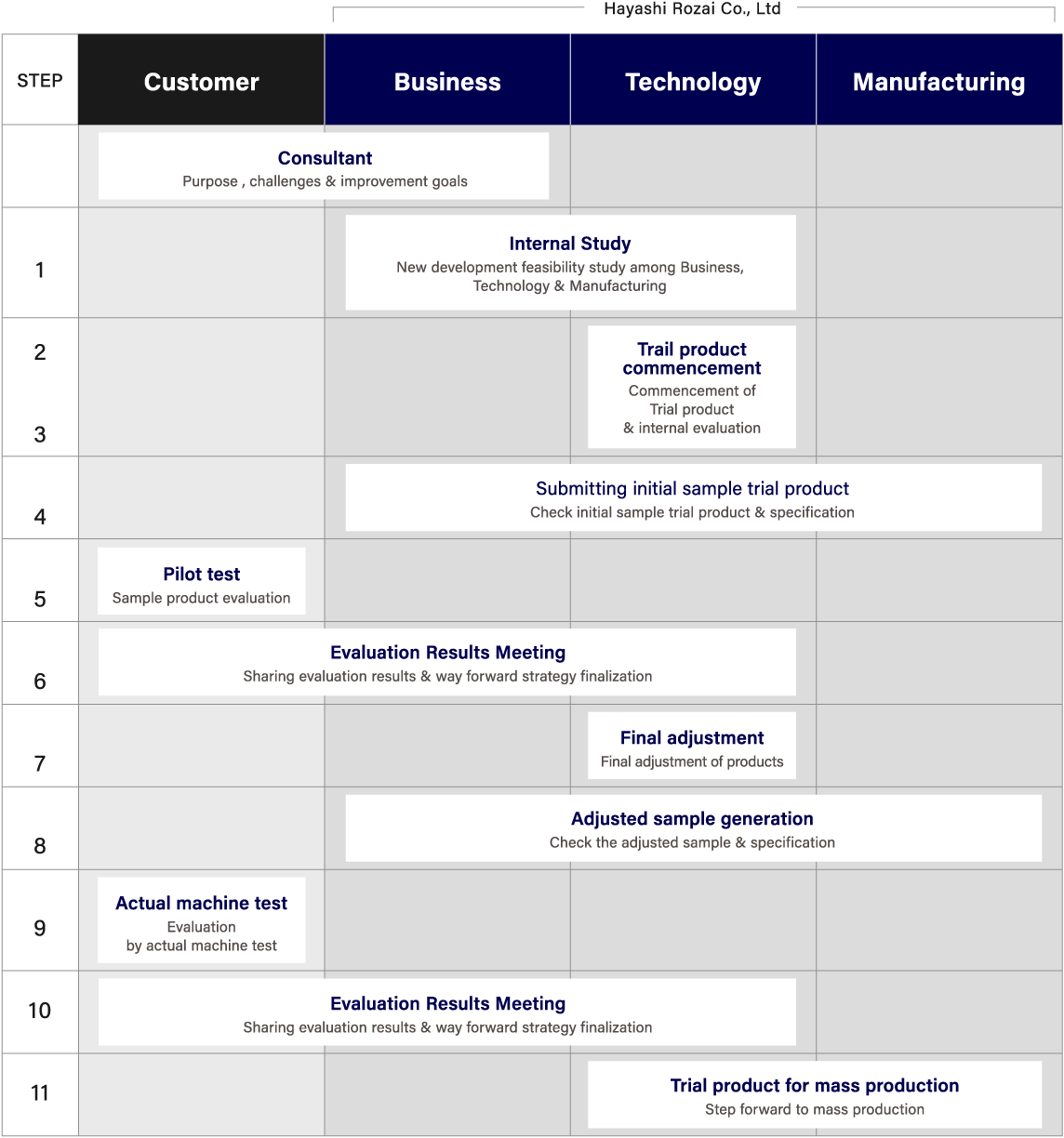

In recent years, due to the diversification of furnace operating conditions, refractories are increasingly used in more severe environments, and a wide variety of requirements arise for improving durability and safety. At our company, in order to clear the customers' problems and improvement goals, we deal with not only standard lineup products but also custom-made development. By repeating trial product and testing many times, we will work together to develop products to meet the customers' needs.

We consider what we can do and propose, listening to your requests and issues.

After considering new development in sales, technology, and manufacturing, we will make a sample trial product and conduct a prototype test.

We will proceed to mass production, after repeating the test, evaluation, adjustment of the sample product, and completing the final specifications,