Hayashi Rozai has been handling refractory raw materials for more than half a century; it has accumulated experience and achievements as a specialized manufacturer of unshaped refractories. We manufacture mainly unshaped refractories used in blast furnaces, electric furnaces, induction furnaces, reverberatory furnaces, incinerators, etc., and sell them to steel makers, casting makers, and recycling companies.

Bizen brand unshaped refractories manufactured by Hayashi Rozai are used not only in Japan but also in the steel and cast iron industries around the world. We have had a track record of delivering to Japanese steel and cast iron manufacturers in Thailand, Vietnam, Indonesia, Mexico, etc. We have delivered our Bizen brand unshaped refractories to Japanese steel and cast iron manufacturers in Thailand, Vietnam, and Indonesia.

While a wide variety of requests for improving the durability and safety of refractories has been increasing, we have been developing for custom-made products per customers' requests in order to clear customers' issues and improvement goals.

By repeating trial products and testing many times, we will work together to develop products to meet our customers' needs.

Bizen City, Okayama Prefecture, where Hayashi Rosai is located, consists of refractory-related companies producing one-third of Japan's refractories.

Our products' quality is supported by companies supplying a wide variety of high-quality raw materials and materials flexibly and speedily, transportation companies reliably delivering products nationwide, and professional companies being familiar with refractory manufacturing.

We have been striving to meet our users' high expectation by enhancing our equipment for automatic loading work using robots and stirring work using an omni mixer to provide reliable products.

We have established a system to ensure high-mix variable production by the introduction of automatic weighing raw material tanks and high-efficiency mixers.

We check the quantity and quality of the received raw materials and store them in the raw material storage tank by the type and particle size.

Unshaped refractories are materials composing different types and particle sizes of raw materials, so is required weighing the various raw materials stored in the storage tank.

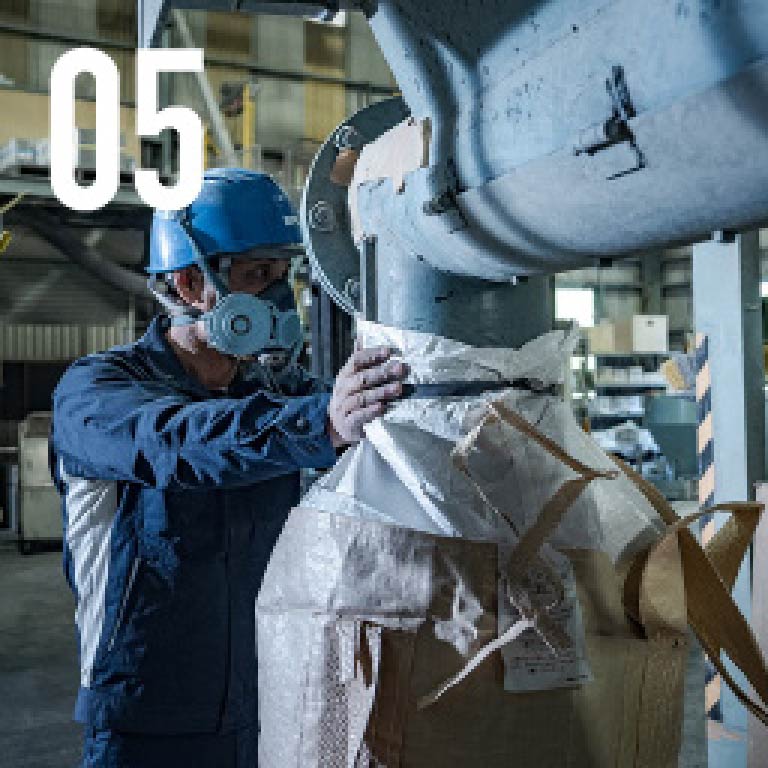

The weighed raw materials are agitated and mixed using a dedicated mixer.

A sample is taken after mixing; quality inspection is performed.

After passing the inspection, the product will be weighed, packaged and then shipped.